In the manufacturing sphere, companies engage in the assembly of prefabricated wall panels at facilities away from the construction site. These panels are meticulously crafted in a controlled environment, tailored to exacting dimensions and specifications predetermined by project needs.

The utilization of this pre-construction strategy considerably decreases the necessity for on-site alterations and measurements, streamlining the build process. A diverse array of materials is employed in the fabrication of these prefabricated wall panels, encompassing wood, metal, concrete, and a selection of composite materials.

This breadth of material choices provides a vast range of options to accommodate various architectural styles and structural requirements inherent in different construction undertakings. The implementation of prefabricated wall panels is thus an integral part of modern construction methodologies, designed to enhance efficiency and adaptability.

The ability of prefabricated wall panels to streamline the construction process and accelerate project timelines stands as one their primary advantages.

Pre-manufactured in a controlled factory environment, these panels equip construction crews for more efficient on-site work; this action reduces labor costs and potential delays.

Builders using these pre-fab panels can achieve faster installation times than with traditional stick-built methods, ensuring that projects are completed on schedule or even ahead of time.

Also read these Eight Practical Reasons To Use Construction Job Costing Software

During the manufacturing process, rigorous quality control measures ensure the consistent quality and adherence to design specifications of prefabricated wall panels.

Precise fabrication in factory conditions minimizes errors and inconsistencies that may arise with on-site construction, enhancing structural integrity and durability of the finished building through this consistent quality control.

Owners and occupants reap long-term benefits from this improved durability.

Prefabrication, through its off-site manufacturing of wall panels, minimizes the material waste often linked with traditional construction methods. It optimizes material usage in factory processes - a factor that leads to less offcuts and leftover materials.

Moreover; it designs prefabricated panels with efficiency as a priority: this maximizes raw material utilization while decreasing overall environmental impact. Contributing to sustainable construction practices, this reduction in material waste holds the potential to secure LEED or other green building certifications for projects.

Utilizing prefabricated wall panels significantly bolsters safety at construction sites: these pre-assembled units abbreviate the duration and scope of on-site work requirements, leading to a substantial decline in potential exposure to hazards.

The diminished necessity for time-consuming and labor-intensive tasks such as cutting, drilling, and heavy lifting while installing these panels leads to a corresponding reduction in the likelihood of accidents or injuries occurring.

Furthermore, due to the rigorous safety standards and protective measures enforced in controlled factory settings where these panels are manufactured, the risks traditionally associated with construction activities on-site are additionally lessened.

Recommended read How To Prevent Hazards In Construction Industry

Prefabricated wall systems often favor the use of insulated metal panel walls or imp walls; these panels provide not only excellent thermal performance but also high energy efficiency. A layer of insulation--expertly sandwiched between metal skins--grants superior thermal resistance and diminishes heat transfer through the building envelope.

Commercial buildings, by integrating these superior insulated metal panel walls into their prefabricated assemblies, can attain elevated levels of energy efficiency: this action culminates in reduced heating and cooling costs over the entire lifespan of the structure.

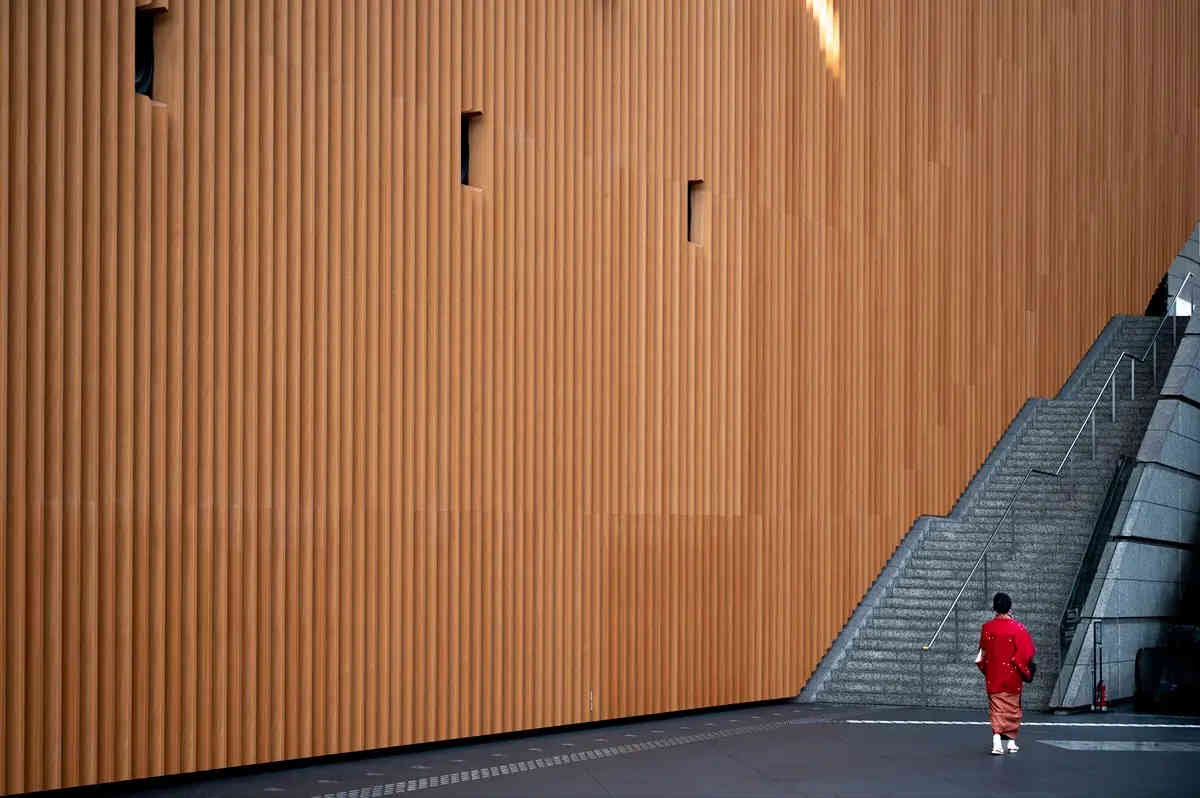

Despite being factory-made, the wall panels offer an extensive range of design malleability and customizations that can be adapted to meet the specific needs of every distinctive undertaking. By forming partnerships with producers, architecture professionals, and creative designers, it becomes feasible to conceive wall panel designs that are uniquely tailored.

Similarly, Colorbond fence panels provide homeowners and commercial property owners with durable, visually appealing fencing solutions that can be customized to complement their architectural style. These designs not only align with but also augment the overall architectural beauty of a building.

These designs not only align with but also augment the overall architectural beauty of a building. The particular appearance and functional requirements of commercial environments can be effectively fulfilled by meticulously customizing prefabricated wall panels.

This customization may involve the careful selection and integration of various architectural nuances, an array of textures, or a selection of finishes, to create a final product that resonates with the envisaged concept.

Engineers have the capability to meticulously design and construct prefabricated wall panels that seamlessly integrate with a building's essential systems, including but not limited to the heating, ventilation, and air conditioning (HVAC), plumbing, electrical frameworks, and insulation requirements.

Recommended read Why You Should Call A Heater Technician For Your Commercial Space

This innovative approach substantially streamlines the usually complex coordination of Mechanical, Electrical, and Plumbing (MEP) services throughout the construction process. It achieves this efficiency by permitting the advanced installation of these integral components within panels that have been expertly built inside factory-controlled environments.

Consequently, builders are able to significantly enhance the overall efficiency and precision of construction projects. They do so by skillfully amalgamating vital structural elements with mechanical systems into these sophisticatedly engineered prefabricated assemblies.

Utilizing prefabricated wall panels in commercial construction endeavors can lead to substantial cost reductions. Though it's possible that the upfront expenses associated with prefabrication may surpass those found with conventional construction techniques, the comprehensive savings achieved through a decrease in labor demands, material costs, and overall project timelines can more than compensate for this initial outlay.

Additionally, the early stages of design offer valuable opportunities for value engineering. These opportunities provide project teams with the ability to refine and optimize panel designs specifically to bolster cost-effectiveness, all while maintaining an unwavering commitment to both quality and structural integrity.

Prefabricated wall panels have emerged as a significant innovation in the realm of commercial construction, streamlining the entire building process with an array of substantial advantages. These benefits span a wide spectrum, including--but certainly not restricted to--the enhancement of efficiency and speed throughout the construction phase, ensuring consistent quality control across various projects, significantly reducing the generation of waste thereby contributing to environmental sustainability.

Furthermore, they promote heightened safety measures on construction sites and offer considerable design flexibility. This versatility indeed translates into pronounced advantages not only for builders and developers but also for building owners who stand to gain immensely.

The adoption of these cutting-edge wall panel systems in prefabricated construction methodologies not only leads to expeditious project completion times but also ushers in cost-efficiency – and notably – brings forth an elevation in performance levels and enhances the sustainability profiles of commercial building ventures.

Find the best Professionals and companies nearby you on KreateCube .

Get QuoteStay updates with latest leads, subscribe now!

Stay updated with latest diy home improvement tips, subscribe now.

Real Estate

07-Oct-2024

Concrete is a durable and widely used construction material, known for its strength and longevity. However, like all materials, it is not immune to damage over time. Identifying early signs of concrete deterioration, such as cracks, spalling, or...

Read MoreReal Estate

11-Mar-2024

The difference between a project that stands the test of time and one that falters can often be attributed to the adherence to a set of critical dos and don'ts. That said, this comprehensive guide is designed to navigate you through the complexities.

Read MoreReal Estate

27-Jan-2024

As we progress deeper into the 21st century, the incorporation of groundbreaking technologies is transforming the landscape of construction machinery. From artificial intelligence to robotics and automation, emerging trends are redefining how...

Read MoreReal Estate

16-Dec-2023

Today, we’re stepping into an amazing era where smart software joins hands with eco-friendly building methods. It’s an exciting combo that’s reshaping so many aspects of our construction world. Let’s explore how this tech isn’t just a fancy term.

Read MoreReal Estate

12-Oct-2023

Selecting a construction company for your project is a decision that can significantly impact the outcome of your venture. Whether you are planning to build a home, an office space, or a commercial complex, the construction company you choose plays..

Read MoreReal Estate

14-Jul-2023

Steel has long been recognized as a versatile and durable material in the construction industry. Its strength, flexibility, and cost-effectiveness make it an ideal choice for a wide range of building applications. In recent years, innovative uses...

Read More

Leave Your Comment